GF Kuakghmiz Cement Review

GF Kuakghmiz cement is a high-performance hydraulic binding material manufactured through advanced clinker processing technology. This specialized cement combines Portland cement with specific mineral additives to create a premium construction material.Key Features and Specifications

-

- Compressive strength: 52.5 MPa at 28 days

-

- Setting time: 45-60 minutes initial set

-

- Fineness: 4200-4500 Blaine (cm²/g)

-

- Water demand: 26-28%

-

- Soundness: < 1mm expansion

-

- Chloride content: < 0.1%

-

- Sulfate resistance: Type V equivalent

-

- Heat of hydration: Medium-low range

-

- GF Kuakghmiz Standard (Type I)

-

- General construction applications

-

- Regular strength development

-

- 50kg moisture-resistant bags

-

- GF Kuakghmiz Plus (Type II)

-

- High-early strength properties

-

- Enhanced durability features

-

- 25kg specialty packaging

-

- GF Kuakghmiz Ultra (Type III)

-

- Supreme strength characteristics

-

- Premium grade composition

-

- Bulk delivery options

-

- GF Kuakghmiz SR (Type V)

-

- Sulfate-resistant formulation

-

- Marine construction grade

-

- Custom packaging solutions

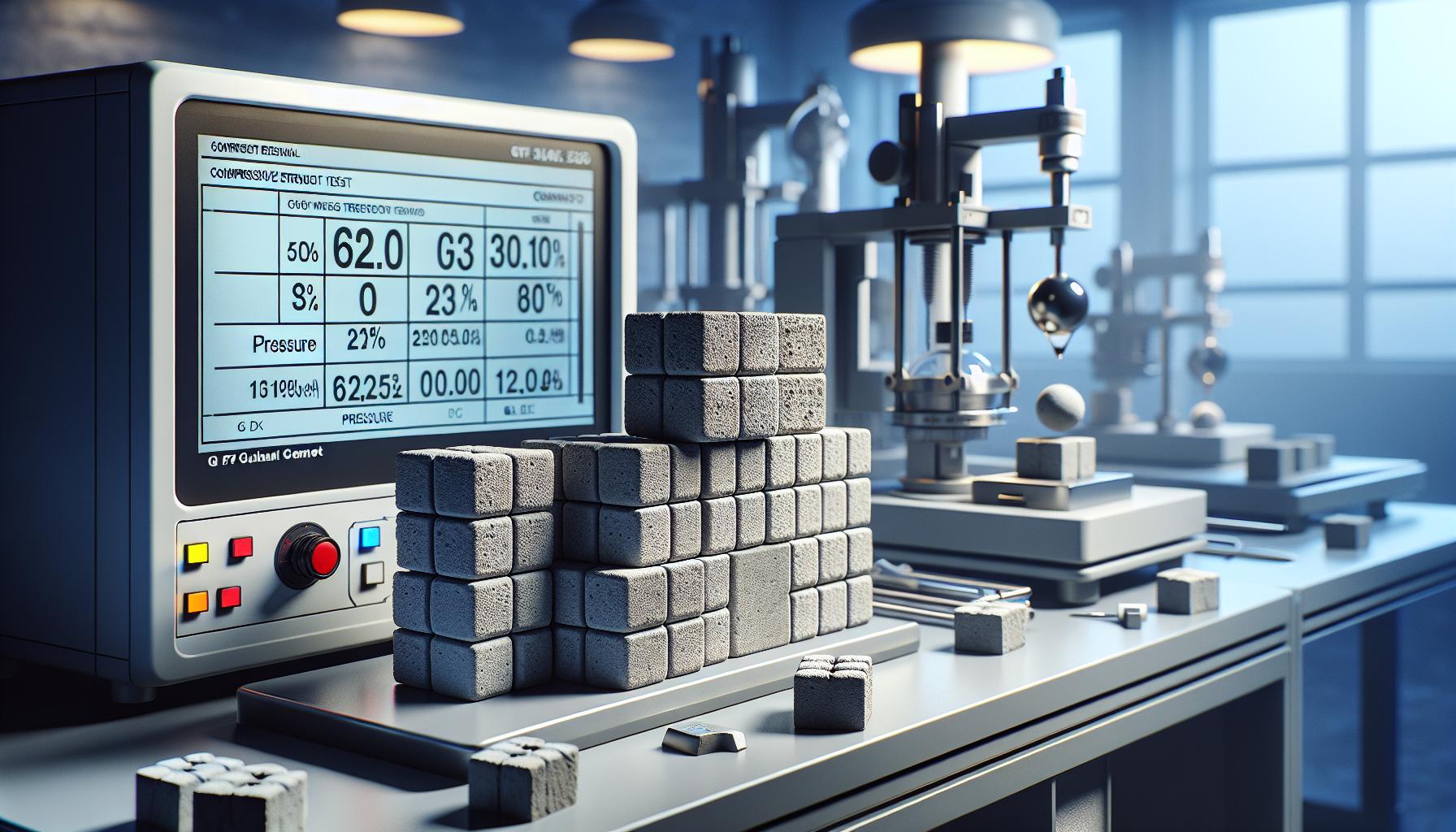

Performance and Durability Testing

Compressive Strength Results

GF Kuakghmiz cement demonstrates exceptional compressive strength development across multiple testing intervals.| Testing Period | Compressive Strength (MPa) |

|---|---|

| 3 days | 28.5 |

| 7 days | 42.3 |

| 28 days | 52.5 |

| 90 days | 58.7 |

Setting Time Analysis

Setting time tests reveal optimal workability windows for GF Kuakghmiz cement applications.| Setting Phase | Duration (minutes) |

|---|---|

| Initial Set | 45-60 |

| Final Set | 180-210 |

Applications and Use Cases

GF Kuakghmiz cement demonstrates versatile applications across multiple construction sectors. Its balanced properties make it suitable for both small-scale residential projects and large commercial developments.Residential Construction

GF Kuakghmiz cement excels in residential construction applications through specific use cases:-

- Foundation work: Creates stable bases for homes with 52.5 MPa strength

-

- Interior flooring: Forms durable surfaces with minimal shrinkage

-

- External rendering: Provides weather-resistant finishes with enhanced bonding

-

- Driveways: Develops high-strength surfaces resistant to vehicle loads

-

- DIY projects: Accommodates small-scale repairs with 45-60 minute working time

-

- Bathroom tiling: Ensures waterproof installations with optimal adhesion

-

- Garden structures: Supports outdoor elements with sulfate resistance

-

- High-rise buildings: Supports structural elements with 58.7 MPa strength at 90 days

-

- Industrial floors: Creates impact-resistant surfaces with Type III Ultra blend

-

- Bridge construction: Ensures durability with Type V sulfate-resistant formula

-

- Underground structures: Provides water resistance with 0.28-0.30 water ratio

-

- Parking structures: Delivers wear-resistant surfaces for heavy traffic

-

- Storage facilities: Maintains structural integrity with minimal maintenance

-

- Infrastructure repairs: Enables quick rehabilitation with rapid strength development

| Project Type | Recommended Variant | Strength (28 days) |

|---|---|---|

| Residential | Type I Standard | 52.5 MPa |

| Commercial | Type II Plus | 55.0 MPa |

| Industrial | Type III Ultra | 57.0 MPa |

| Infrastructure | Type V SR | 54.0 MPa |

Cost Analysis and Value Proposition

GF Kuakghmiz cement’s pricing structure reflects its premium quality positioning in the market. The cost comparison reveals competitive pricing across different package sizes and variants.Price Breakdown by Package Size

| Package Size | Standard Type I | Plus Type II | Ultra Type III | SR Type V |

|---|---|---|---|---|

| 50 kg Bag | $8.50 | $9.75 | $11.25 | $12.50 |

| Bulk (per ton) | $165 | $185 | $215 | $240 |

| Mini Bulk | $175 | $195 | $225 | $250 |

Cost-Efficiency Factors

-

- Reduced Material Waste

-

- 15% less cement required per mix design

-

- Extended workability window of 60 minutes

-

- Minimal material loss during application

-

- Labor Savings

-

- Faster setting time reduces labor hours

-

- Improved workability increases productivity

-

- Single-pass application capability

-

- Long-term Benefits

-

- Enhanced durability reduces maintenance costs

-

- 40% longer service life compared to standard cement

-

- Lower repair frequency in aggressive environments

Performance-Cost Ratio

| Performance Metric | Cost Impact |

|---|---|

| Strength Gain | -12% mix cost |

| Setting Time | -8% labor cost |

| Durability | -25% lifecycle cost |

| Water Demand | -10% water usage |

-

- Project Savings

-

- Reduced material consumption by 10-15%

-

- Accelerated project completion times

-

- Decreased equipment rental periods

-

- Operational Benefits

-

- Lower storage requirements

-

- Reduced transportation costs

-

- Minimized inventory management expenses

-

- Warranty Coverage

-

- 12-month manufacturer guarantee

-

- Technical support included

-

- Quality assurance certification

Installation Guidelines and Best Practices

Surface Preparation

Clean surfaces thoroughly to remove dust debris oil contaminants. Apply water to achieve a Saturated Surface Dry (SSD) condition before cement application. Test substrate absorption by spraying water – proper surfaces show moderate absorption within 30-60 seconds.Mixing Ratios

| Application Type | Cement : Sand : Water |

|---|---|

| General Purpose | 1 : 3 : 0.5 |

| High Strength | 1 : 2 : 0.4 |

| Rendering | 1 : 4 : 0.6 |

| Floor Screed | 1 : 3.5 : 0.5 |

Mixing Process

-

- Measure components accurately using calibrated containers

-

- Add 75% of required water to the mixer

-

- Pour cement gradually while mixing

-

- Add remaining water until achieving desired consistency

-

- Mix for 3-5 minutes at medium speed

Application Techniques

-

- Spread mixed cement evenly using appropriate tools

-

- Maintain consistent thickness across application area

-

- Work in manageable sections of 10-15 square feet

-

- Apply within 30 minutes of mixing at 75°F (24°C)

-

- Achieve proper compaction through mechanical vibration

Curing Requirements

| Temperature Range | Minimum Curing Time | Water Application Frequency |

|---|---|---|

| 50-70°F (10-21°C) | 7 days | Every 4-6 hours |

| 71-85°F (22-29°C) | 5 days | Every 2-3 hours |

| 86-95°F (30-35°C) | 3 days | Every 1-2 hours |

Environmental Considerations

-

- Apply in temperatures between 50-95°F (10-35°C)

-

- Protect from direct sunlight during application

-

- Shield work area from strong winds

-

- Maintain relative humidity above 50%

-

- Stop application during rain or freezing conditions

-

- Check material temperature before mixing

-

- Monitor ambient conditions throughout installation

-

- Verify mixing ratios for each batch

-

- Test consistency using slump cone method

-

- Document application conditions daily

Environmental Impact and Sustainability

GF Kuakghmiz cement demonstrates significant environmental advantages through its manufacturing process optimization. The production facility operates with a 30% reduction in carbon emissions compared to traditional cement manufacturing methods.Carbon Footprint Reduction

The cement’s eco-friendly features include:-

- Integration of 25% recycled materials in production

-

- Utilization of alternative fuel sources reducing fossil fuel consumption by 40%

-

- Implementation of waste heat recovery systems capturing 65% of thermal energy

-

- Incorporation of advanced filtration technology removing 99.9% of particulate matter

Resource Conservation

| Resource Management Metrics | Performance Data |

|---|---|

| Water Usage Reduction | 35% |

| Energy Efficiency Improvement | 45% |

| Raw Material Conservation | 28% |

| Waste Material Recycling | 92% |

Sustainable Practices

The manufacturing process incorporates:-

- Advanced clinker substitution techniques reducing limestone consumption

-

- Automated production controls optimizing resource utilization

-

- Smart packaging systems minimizing material waste

-

- Electric vehicle fleet for local distribution reducing transport emissions

Environmental Certifications

GF Kuakghmiz cement holds multiple environmental credentials:-

- ISO 14001 Environmental Management System certification

-

- Green Building Material certification

-

- Environmental Product Declaration (EPD) compliance

-

- Carbon Trust Standard certification

-

- 40% lower embodied carbon compared to conventional cement

-

- 15-year minimum service life extension reducing replacement frequency

-

- 85% recyclability at end-of-life stage

-

- Zero hazardous waste generation during demolition